Plant-based carpets

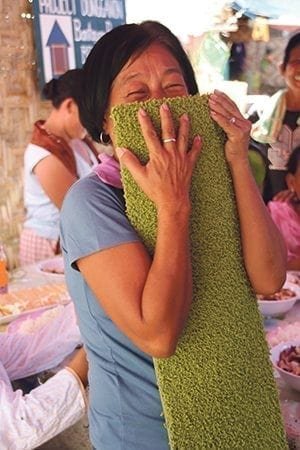

In 2012, Interface launched Fotosfera, the first ever carpet tile made from plant-based nylon. The product consists of yarn exclusive to Interface, which is made from castor bean plants and produced in rural communities. The oil’s derived from plants that are fast-growing, resilient and exceptionally low-maintenance. 70% of the world’s castor bean plants are grown in India; even in hot, arid conditions they may only require water once in up to 25 days.

By using castor bean plants in Fotosfera, Interface made a breakthrough in an industry that’s traditionally relied on petroleum-based materials. At the same time as reducing its reliance on virgin petro-chemical raw materials, with the ultimate goal of eradicating them from its products by 2020, Interface has helped to deliver significant socio-economic benefits by supporting the farmers who grow the crops. Castor bean plants act as an excellent soil stabiliser in areas prone to erosion and can grow on marginal land where other crops struggle, providing farmers with a much-needed income. In some circumstances, this can lead to a revenue of up to 10 times the cost of planting the crop.

As well as having 63% bio-based content, Fotosfera uses Interface’s glue-less installation method, TacTiles™, to further reduce the product’s impact on the environment by virtually eliminating Volatile Organic Compounds (VOCs). This approach removes liquid adhesives from the installation process and can help to contribute to a healthier environment, with a lower impact on indoor air quality.

What’s more, using a glue-free installation method means that there will be no damage to the sub-floor if carpet tiles are taken up, which allows more design flexibility and can make repairs and recycling easier when it’s time to replace the carpet.

Mission Zero

The focus on sustainability and the ‘war on waste’ are part of Interface’s Mission Zero pledge, which made Interface one of the first companies to make a public commitment to sustainability. The goal is for Interface to become the first fully sustainable — and ultimately restorative — company and to achieve zero negative impact by 2020.

Since Mission Zero began, Interface has successfully achieved zero waste to landfill status at its European manufacturing facility in Scherpenzeel, the Netherlands, and continues to introduce new solutions to environmental issues. The company has achieved a 50% reduction in energy use per unit of production and an 87% reduction in water consumption. Water use is expected to drop to around 95% following Interface’s recent installation of a recirculation system that uses closed-loop piping.

In January 2014, the Dutch plant confirmed the site was operating on 100% renewable gas and electricity, with green gas created by the anaerobic digestion of fish waste. As a result, Interface was able to announce earlier this year that it had achieved a 90% carbon reduction.

Sustainability and design

The way Interface sees it, sustainability and design go hand in hand — a sustainable solution needs to be practical and aesthetically pleasing and with that in mind, there should never be a need to compromise. In recent years the company has won key design awards including the Red Dot award and the Athaneum Good Design Award in 2012.

The way Interface sees it, sustainability and design go hand in hand — a sustainable solution needs to be practical and aesthetically pleasing and with that in mind, there should never be a need to compromise. In recent years the company has won key design awards including the Red Dot award and the Athaneum Good Design Award in 2012.

There’s a genuine belief at Interface that the only way to achieve long-term sustainability is to listen to people and their opinions, no matter who they are. Interface is a business and as such it’s driven by demand, so it needs to create practical solutions to real issues. There’s little sense in creating highly sustainable products if customers aren’t prepared to buy them.

Every customer’s needs are different — some may want a bold, colourful design, whereas others may want a more muted, conservative scheme, but all will undoubtedly want a product that is durable and that withstands the test of time in a busy environment.

The glue-less installation method of TacTiles is a perfect example; in addition to the environmental benefits of eradicating the use of adhesives, there are design benefits to bonding carpet tiles to each other rather than to the floor. Those in listed properties don’t need to worry about causing damage to the floor underneath the carpet, and the tiles allow you to explore your creative side by mixing styles and colours, or cutting tiles into different shapes for a unique pattern.

The result is a durable installation without the daunting permanence of experimentations with bold patterns or vibrant colours. Businesses hosting events can also print bespoke designs, such as QR codes, onto the tiles.

Driving transparency

Interface has devised strict methods for measuring sustainability — not just in order to monitor its progress with Mission Zero, but also to help customers understand what is involved in truly sustainable business. As a result, it’s allowing consumers and businesses to make more informed decisions about the products they select.

The company understands that, in order to be sustainable, you need to take into account the full life cycle of a product. Using Life Cycle Assessments (LCAs) enables any business to develop an in-depth understanding of a product’s environmental impact during its entire life cycle, from the sourcing of raw materials and manufacture right through to installation, maintenance and disposal.

This commitment to business transparency meant Interface was the first carpet tile manufacturer to receive a third-party verified Environmental Product Declaration (EPD), to allow true product comparisons. Interface is actively encouraging this level of transparency across the industry in general, and believes that the shift towards these standards represents true innovation. For customers, the practical result is that you can make informed decisions about the products you buy and the impact they have.

For more information on Interface, its Mission Zero pledge and the Net-Works scheme, visit interfaceflor.co.uk.

Play Video about This Rock Might Just Save The World

Play Video about This Rock Might Just Save The World Play Video about Play 2 hours of rock

Play Video about Play 2 hours of rock Play Video about Play 2 hours of brook

Play Video about Play 2 hours of brook Play Video about Play 2 hours of sheep

Play Video about Play 2 hours of sheep

Circular thinking started at Interface around 20 years ago, when founder Ray Anderson decided to uproot fundamental principles of the business. His ‘outrageous’ expectation was that the company should ‘cut the umbilical cord with oil’ — the main product traditionally used in nylon yarn.

Circular thinking started at Interface around 20 years ago, when founder Ray Anderson decided to uproot fundamental principles of the business. His ‘outrageous’ expectation was that the company should ‘cut the umbilical cord with oil’ — the main product traditionally used in nylon yarn. Interface was the first company of its kind to identify the problems associated with nylon yarn in the manufacture of carpet. The company carried out research on its own manufacturing process and discovered that, throughout the full life cycle of its products, the manufacturing of the yarn causes the greatest harm to the environment.

Interface was the first company of its kind to identify the problems associated with nylon yarn in the manufacture of carpet. The company carried out research on its own manufacturing process and discovered that, throughout the full life cycle of its products, the manufacturing of the yarn causes the greatest harm to the environment. The way Interface sees it, sustainability and design go hand in hand — a sustainable solution needs to be practical and aesthetically pleasing and with that in mind, there should never be a need to compromise. In recent years the company has won key design awards including the Red Dot award and the Athaneum Good Design Award in 2012.

The way Interface sees it, sustainability and design go hand in hand — a sustainable solution needs to be practical and aesthetically pleasing and with that in mind, there should never be a need to compromise. In recent years the company has won key design awards including the Red Dot award and the Athaneum Good Design Award in 2012.